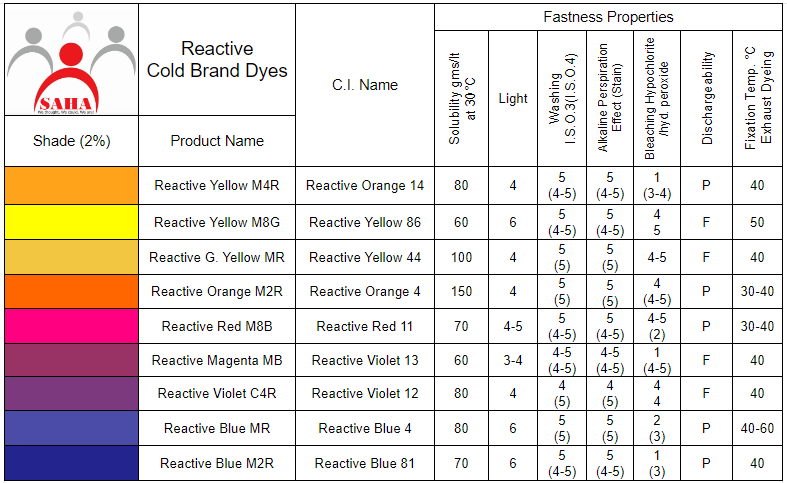

Cold Brand Dyes are highly reactive dyes, for that reason it requires a very mild condition to fixation with fabric. These dyes have very good fastness properties. Using these dyes exhaust dyeing is done at low temperatures like 30- 40°C and printing is not recommended with these dyes. These dyes are suitable on all major popular dyeing machines.

Dyeing Procedure of Cold Brand Reactive Dyes:

Preparation of Cotton for Dyeing:

Bleached material for dyeing must be free from alkali; this prevents premature localized fixation and improves leveling of the dyes.

Preparation of Dye Solution:

The Cold Brand (M brand) dyes are putted with cold water dissolved by adding water at 50°.

Dyeing Cycle:

Make the dye bath pH to 6.5 – 7 with acetic acid on the wing. Add a suitable liquor ratio for 10 minutes at room temperature. After 15 minutes add the acid pre dissolved common salt or glauber's salt and dye for another 30 minutes. Add pre dissolved alkali (soda ash) and continue dyeing it for another 30 min and then drain the dye bath .Tthe salt and the alkali may be added in two portions. Wash the material properly after dyeing in cold running water for 10 minutes.